Testing Facilities

Thickness test :

To ensured that the coating thickness meet our customer standard. The plating thickness of the customer part is tested. Test method used is the Magnetic induction method.

Although there are quite a few electroplating tests involved in evaluating the quality of the plated parts, we are only concern with two most common plating requirement which is Thickness test and Salt Spray Test.

Available inhouse testing equipment consist of:

- UEP FISCHER Thickness Testing Equipments

Salt Spray Test :

To test corrosion resistance. Items to be tested are enclosed in the salt spray chamber and immerse in a mist of 5% sodium chloride solution (source JIS Z2371:2000) Time taken for white and red rust appearing are noted and exceed the minimum standard set. All testing would be in adherence to NSS test requirement as per customer specification.

The salt spray tests are particularly useful for detecting discontinuities, such as pores and other defects in certain metallic, organic, anodic oxide and conversion coatings.

The neutral salt spray test applies to:

- metals and their alloys;

- metallic coatings (anodic and cathodic);

- conversion coatings;

- anodic oxide coatings;

- organic coatings on metallic materials.

UEP Neutral SST Machine

Other Testing Facilities:

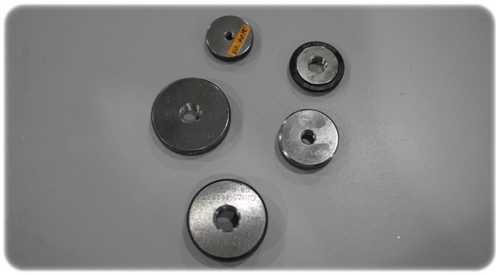

- Ring Gauges – Bolt Thread

- To ensure Bolt thread does not have gauge tight issue which would lead to friction co-efficient problems.

Watch How We Work

Address:

No.1 Solok Selat Selatan 21A, Sobena Jaya Industrial Estate, Pandamaran, 42000 Port Klang, Selangor Darul Ehsan Malaysia

Email:

ulision@ulisionep.com sunkh@ulisionep.com

Open Hours:

Mon-Sat: 8am - 5pm